FLOWDRIFT Gear Pump KGP-06D Series

FLOWDRIFTTM DC 24V Electric Gear Pump Stepper Motor Magnetic Drive High Pressure Gear Pump 25Bar Max Stainless Steel Gear Pump KGP-06D Series with Controller Quiet Working Food Grade for Hot Water 0-100℃ High Viscosity 3000CPS Allowed

KGP-06D / DC24 Magnetic drive gear pumps, using DC Stepper motor-driven, the outer shaft and rare earth permanent magnet Motor connection, magnetic drive gear pump. Configuration independent Stepper motor drives, you need to control their PC, for single-cylinder to achieve speed control function can also be configured for speed pulse generator which is characterized by Rev. adjustable, with speed and reverse rotation, low noise, and small size. KGP-06D full range of gear pump head can use Stepper motor.

KGP-06D / DC24 magnetic drive gear pump, magnetically coupled transmission without leakage, 316 stainless steel material precision machined housing, PEEK machined gear, static sealing made of PTFE material. The pump can be used in a -0.1Map-2Map closed system. The rated output pressure is 5bar, the maximum output pressure is 15bar, and the output flow rate is 50-3000ml/min. Widely used in hemodialysis machines, inkjet printers, inkjet printers, pharmaceutical, chemical, water treatment, printing, cleaning, packaging, filling machines, food processing and other fields of liquid metering and transportation. It is especially suitable for construction machinery, vehicle equipment, and automobile exhaust gas treatment.

Model specification

| Model | KGP | 06D | 04/09/13 | / | DC24 | ||

| Position | KGP-06D full range of gear pumps | 1 | |||||

| 1 | Motor Types | DC24 = straight DC 24V power stepper motor | |||||

Features

1. Motor Power: 50W

2. Speed Control: Built-in drive voltage 0 ~ DC5V governor.

3. 0 ~ 5V pulse signal output for speed or constant speed control.

4. Altitude: ≤ 2500 meters

5. Ambient humidity: ≤ 75%

6. Fluid viscosity: 0 ~ 3000CPS

7. Ambient temperature: -30 ~ 50 ° C

8. Fluid temperature: -10 °C ≤ T ≤ 100 ° C (except for freezing)

9. Working style: continuous working system

10. Use medium: acid, alkali, salt, organic solvent, oil at room temperature.

Suitable areas

• Automotive • Food processing equipment • Medical equipment • Water Cycle

• Packaging Machinery • Vending machines • inkjet printer, inkjet printers • detection equipment

Technical parameters

| Model | preset pressure | flow | Power | System pressure | Rev. | Medium viscosity |

| KGP-06D04/DC24 | 5bar | 5~160 ml/min | 50W | -0.8 to 20bar | 200-4000rpm | 0.2 ~ 3000cps |

| KGP-06D09/DC24 | 10~330 ml/min | |||||

| KGP-06D13/DC24 | 15~450 ml/min |

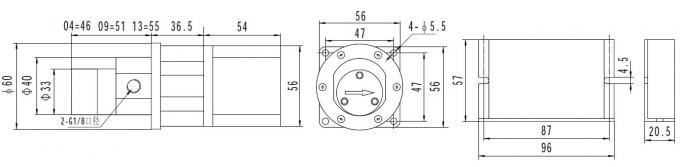

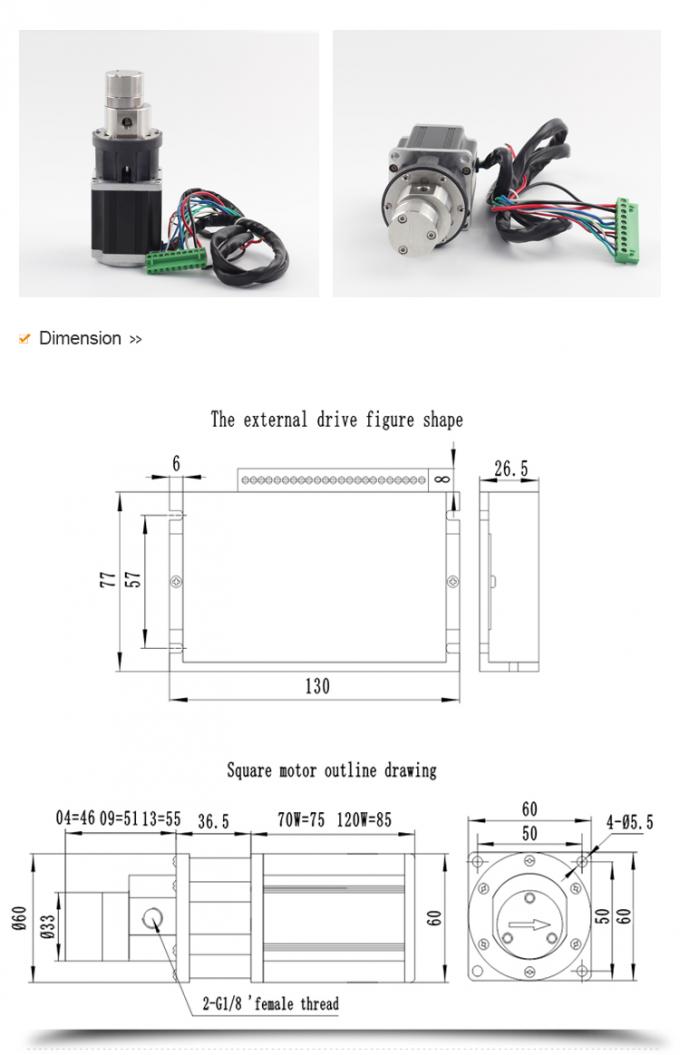

Outline dimension chart:

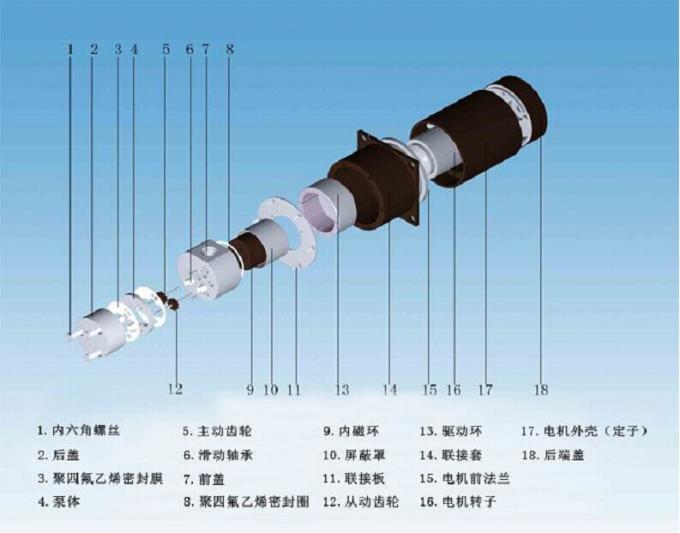

Exploded View

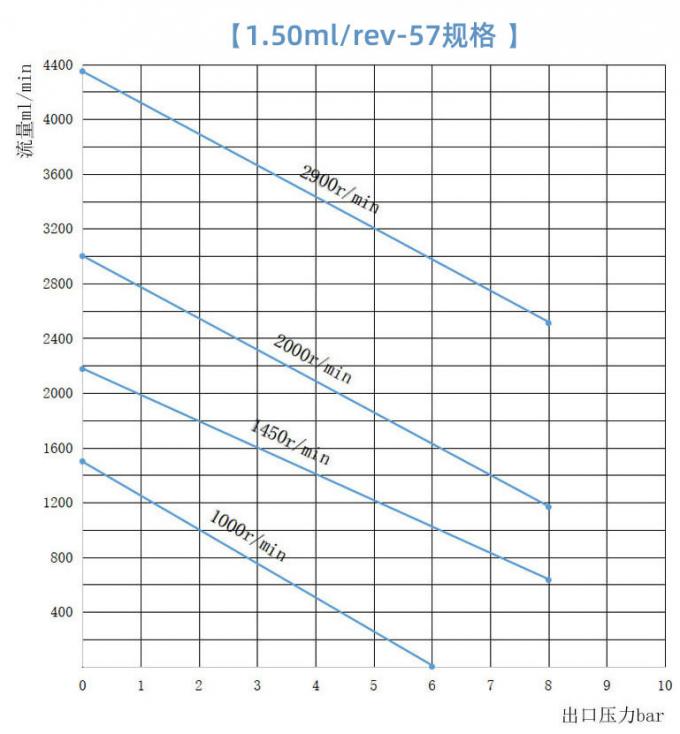

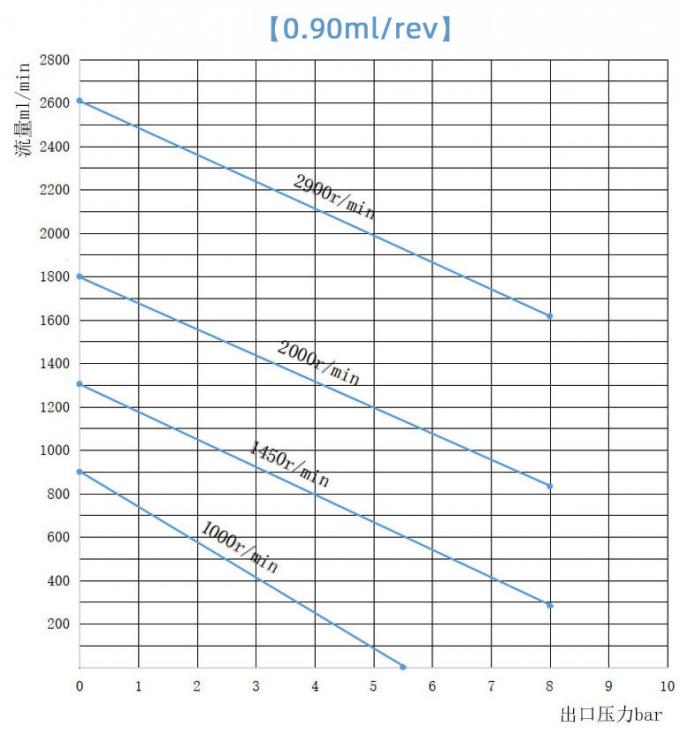

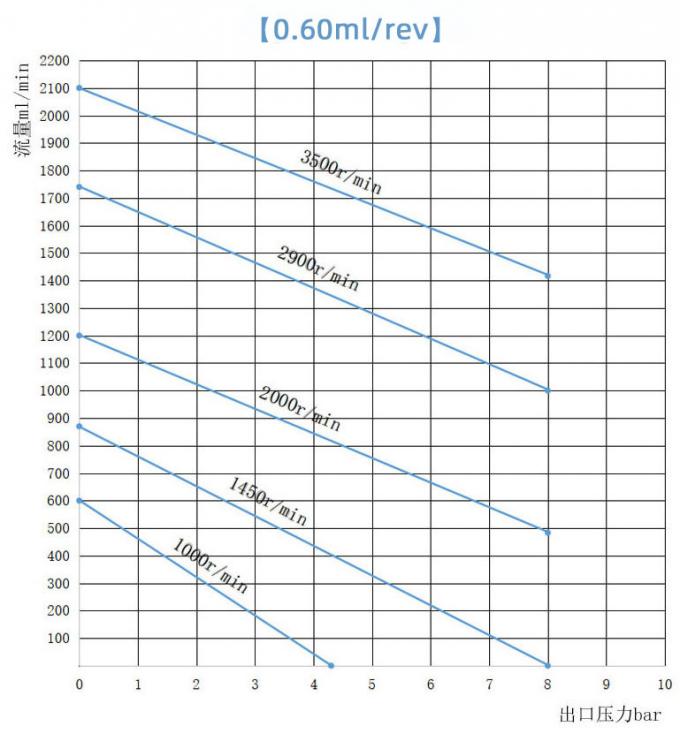

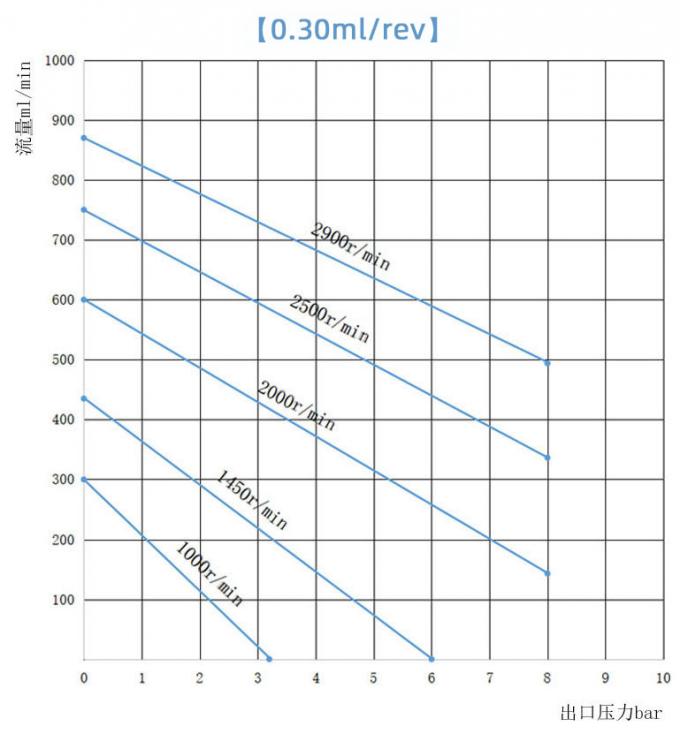

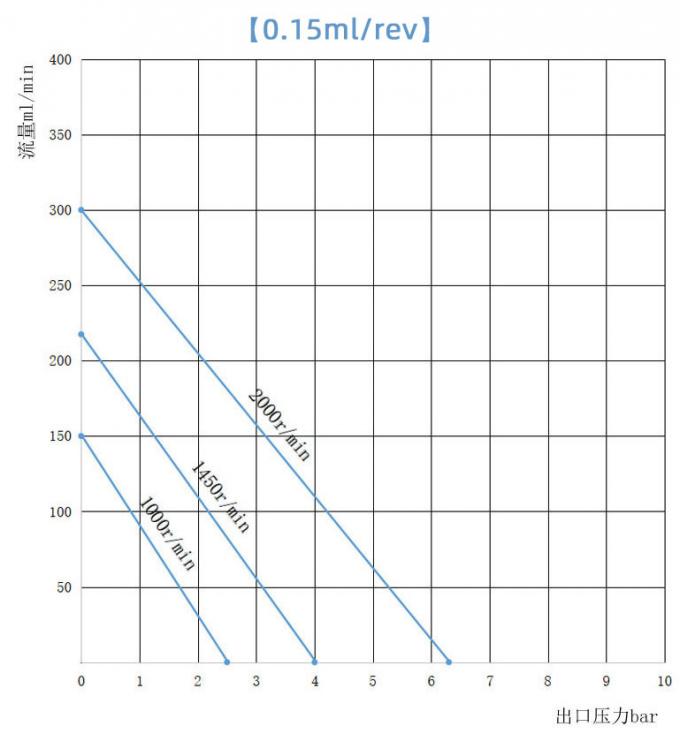

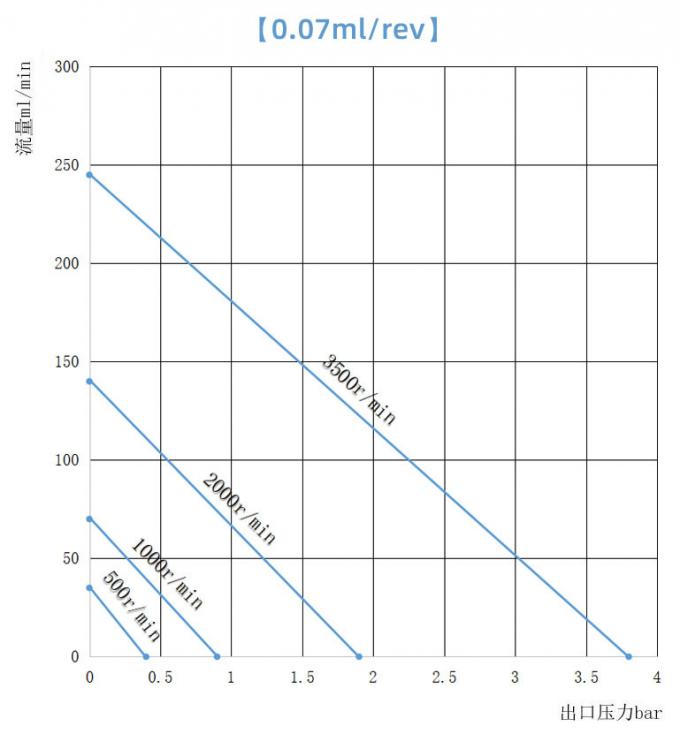

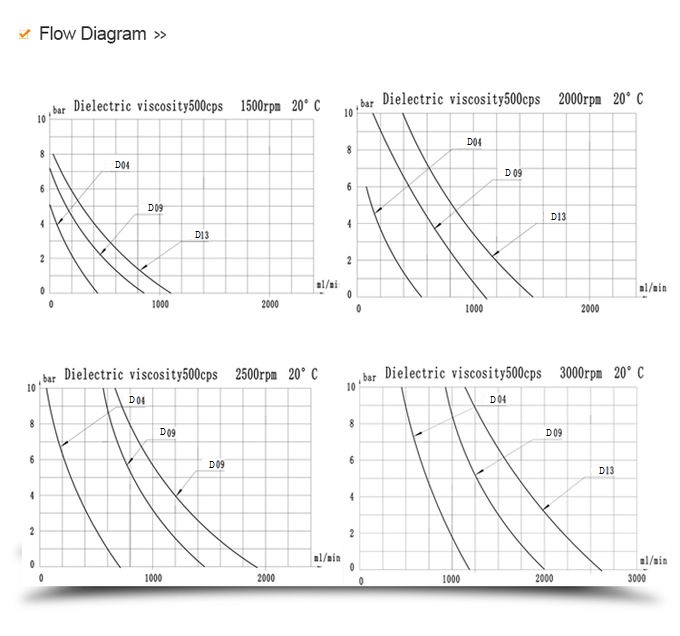

More demand curves:

CHEMICAL RESISTANCE

| Chemical Resistance Code | Max Temperature Resistance Code |

|

A -- Excellent B -- Good C -- Ordinary × -- Unacceptable - -- Unusable |

1-20 ℃(68F) 2-40 ℃(104F) 3-60 ℃(140F) 4-80 ℃(176F) 5-100 ℃(212F) 6-120 ℃(248F) |

| CHEMICAL | MATERIAL | |||||||

| PP | PTFE | FKM | NBR | EPDM | 95 Ceramic | |||

| Sulfuric Acid | 0-10% | A4 | A6 | A6 | B2 | A4 | A5 | |

| 10-75% | A3 | A6 | A4 | X | A3 | A5 | ||

| 75-100 percent | B2 | A4 | A4 | - | B2 | A5 | ||

| Nitric Acid | 10% | A3 | A5 | A5 | X | A2 | A5 | |

| 30% | A2 | A6 | A6 | X | A2 | A5 | ||

| 50% | B2 | A3 | A1 | X | X | A5 | ||

| Hydrochloric Acid | 0-25% | A4 | A6 | A3 | B1 | C3 | A5 | |

| 25-40% | A4 | A6 | A2 | X | C2 | A5 | ||

| Hydrofluoric Acid | 10% | B2 | A6 | A3 | X | A3 | - | |

| 30% | C2 | A6 | A4 | - | B3 | - | ||

| 60% | X | A6 | A4 | - | C2 | - | ||

| Acetic Acid | 20% | A2 | A6 | B1 | B2 | A2 | A5 | |

| 80% | B1 | A6 | X | - | - | A5 | ||

| Sodium Hydroxide | 20% | A3 | A6 | B1 | B2 | A3 | - | |

| 50% | A3 | A6 | X | B1 | A4 | - | ||

| Bromine Water | C1 | A3 | A2 | - | X | A1 | ||

| Ethyl Alcohol | A2 | A3 | A3 | X | B3 | A3 | ||

| Acetone | A2 | A6 | X | - | B2 | A3 | ||

| Freon 12 | X | A6 | A1 | X | B1 | A4 | ||

| Aluminum Chloride | A4 | A6 | A5 | B4 | A4 | A4 | ||

| Ammonia Liquid | A1 | A6 | C1 | B4 | B3 | A3 | ||

| Aqua Regia | C2 | A5 | B2 | - | C2 | A4 | ||

| Formaldehyde | A4 | A6 | A4 | X | A4 | A4 | ||

| Gasoline | X | A6 | B3 | B3 | X | A4 | ||

| Kerosene | A1 | A6 | A1 | B1 | X | A4 | ||

| Methyl Alcohol | A3 | A6 | B2 | B4 | A3 | A5 | ||

| Toluene | C1 | A4 | B1 | - | X | A5 | ||

| Trichloroethylene | C1 | A6 | A1 | - | X | A4 | ||

| Xylene | X | A6 | B1 | - | X | A5 | ||

| Nitric Acid Anhydrous | C1 | A3 | A1 | - | X | A5 | ||

| Oleum | X | A6 | A4 | - | X | A5 | ||

| Potassium Hydroxide | A4 | A6 | B1 | C2 | A5 | - | ||